The Paint Project Retrofit Installation - Hussey Seating

The Following is an After Install Report for the Hussey Seating Gema Retrofit:

Scope:

The Retrofitting of the Old Inefficient Gema Automatic Powder Guns, Controllers and Rotary Oscillators.

- The GM02 Automatic Powder Guns were up graded to the advanced GM03 Automatic Powder Guns with CG20 gun controllers.

- The rotary oscillators were replaced with ZA07 Reciprocators and XT10 in/out positioners.

- The retrofit l also includes the addition of a CM40 MagicControl 4.0, Automation and Triggering Package, integrated into the existing OptiCenter.

- A full Light Curtain was added for automatic gun triggering.

Reasons for Retrofit:

The existing Gema system was lacking in certain efficiencies that caused high rates of powder waste & man hours. Color changes where taking in excess of 30 minutes to complete and involved extra unnecessary actions by the operators in order to assure that no cross color contamination would happen.

Upon conducting a Flow test on the automatic guns in October of 2020, it was determined that they were operating at a 35% efficiency rate.

With a 35% Transfer Efficiency, for every 5-6oz of powder that is applied to a part 10-11oz goes past the part and into the collection system.

This results in higher powder output settings leading to more powder wasted, operators working harder to manual coat parts that do not necessarily need manual intervention and wear parts requiring more frequent replacement.

The only automation in the existing system was the powder delivery and the powder reclaim.

With the high output of powder and low level of automated color change, the color change process took significantly longer than needed and cross contamination events was more prevalent.

Upon Hussey’s decision to go forward with the retrofit upgrades, the following is the scope of the installation:

- Removal of the old controls and equipment

- Mechanically install all of the new equipment & components

- Unpack and physically place the reciprocators and the positioners

- Unpack, construct and place light curtain

- Unpack and place control cabinet

- Unpack and assemble guns and gun bars to reciprocators

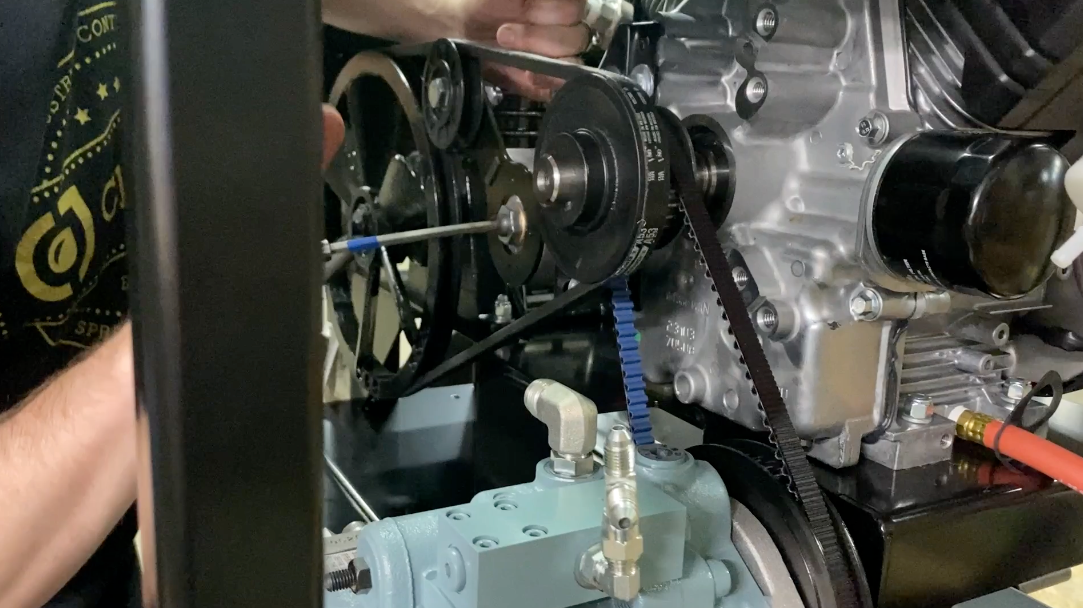

- Install conveyor encoder

- Run all required wiring, Powder Hoses and airlines

- Adapting the new electronics to the existing system

- Calibrate, program and test the system with powder

- Train maintenance, supervisory & engineering personnel

- Train operators

This succesful retrofit has already generated substantial savings in powder usage and required man hours.

The GM02 Automatic Powder Guns were up graded to the advanced GM03 Automatic Powder Guns

Upgraded control center featuring CG20 gun controllers

The rotary oscillators were replaced with ZA07 Reciprocators and XT10 in/out positioners

CM40 MagicControl 4.0 automation and triggering package